The Glue Talk Blog

Problem Solving: Tailored adhesives for reducing packaging materials

Manufacturers and brand owners are facing steep increases in their packaging costs, largely due to the rising cost of raw materials. Cardboard prices, for example, are currently increasing between 30 to 50 percent as a result of the higher cost of paper from which cardboard is made. In addition, paper prices rose up in 2018, with wood pulp prices up, contributing to a total increase of 43 percent since 2016.

Increased demand for products made from paper

There is a wide range of underlying factors that influence paper price levels. Globally, demand for paper products is on the rise, a trend that is driven by multiple aspects. For example, retailers are continuing to move away from plastic carrier bags and disposable plastic cups to traditional paper bags and recyclable paper cups. Also the increase of online shopping and the subsequent extra need for cardboard packaging. Storm damage to US paper mills in 2018, Brexit uncertainty in Europe, and rising wholesale gas and electricity prices across Europe have also played a role in driving up paper prices.

Faced with increased packaging costs, many manufacturers are currently analyzing what packaging materials they are using and wondering what kind of savings they can achieve while protecting their bottom line. Some are switching to a cost-effective, lighter board grade for their cardboard, others are reducing the size of their boxes or looking at whether they can reduce the number of manufacturing steps involved in their packaging. And, some are taking a bolder approach and getting rid of some packaging altogether.

The dynamic is set and the packaging industry is indeed looking for new ways of achieving considerable cost savings. Industry players and brand owners are actively transitioning from plastic to other packaging materials and yielding environmental and economic benefits. This is currently one of the main drivers, where by having less plastic, you are implementing measures working towards a more circular economy and improving sustainability in the supply chain.

A tailored adhesive to enable cost savings packaging

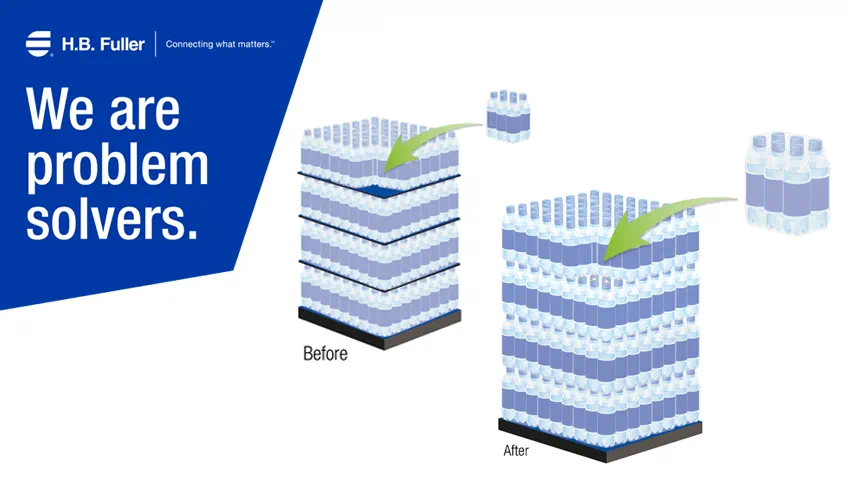

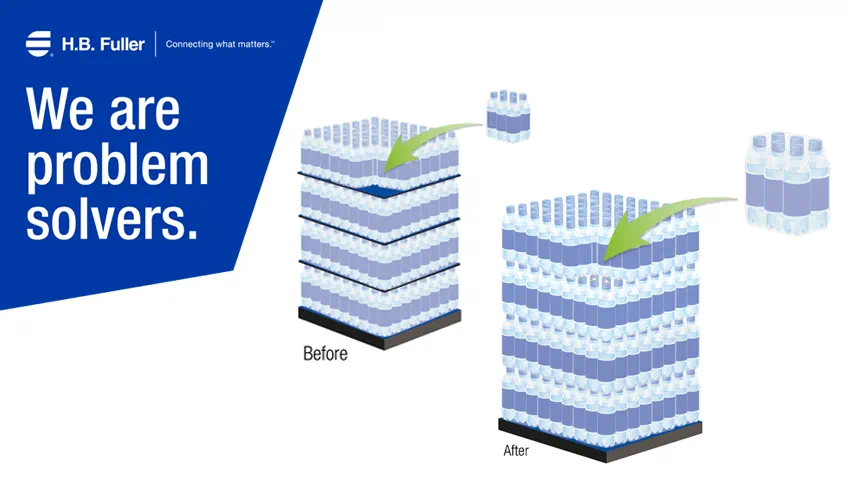

Helping to reduce the overall amount of packaging materials used is where our tailored adhesive Advantra® 9255 LP is proving to be highly effective. Traditionally, manufacturers of PET multi-packs have used slip sheets, essentially a piece of cardboard between the layers of multi-packs to increase pallet stability. These slip sheets have to be inserted and once all the multi-pack layers are in place, the pallet is shrink-wrapped.

Advantra® 9255 LP largely replaces the need for slip sheets. Instead, the bottle multi-packs are kept in place through the application of a small dot of Advantra® 9255 LP on each shrink-wrapped cap, effectively gluing the multi-packs together at the top and bottom.

Invisible to the consumer

Advantra® 9255 LP has low enough viscosity to be sprayed and does not attract dust or angel hair. It's applied by a hot melt dispensing system triggered by an optical sensor, at a temperature that is cold enough so it won’t burn the shrink wrap. The whole process reduces manual handling and when the pallets arrive at their destination, the multi-packs can be easily separated without leaving a visible mark on the six pack.

Significant ongoing savings

It all adds up to an innovative adhesive solution that's addressing a tough marketplace challenge.

With Advantra® 9255 LP, customers are significantly reducing the amount of packaging materials they use and are seeing a return on their investment in less than a year. Depending on the current pallet configuration a customer may use just one slip sheet per pallet instead of three, another customer reduced the amount of shrink wrap to only three full shrink wraps instead of nine, being that the exact savings potential will depend on pallet configuration. All in all, by reducing the amount of raw materials they use and the waste they generate, customers are improving their sustainability performance at the same time.

To explore how our adhesives could help you reduce your organisation's packaging costs, connect with us today.

Blog Categories

Blog Categories

Archive

- 2024

- 2023

- 2022

-

2021

- January (3)

-

February (7)

- Celebrating Exceptional Service During COVID-19 Complications

- Cyanoacrylates: What They Are and What They Do

- Innovative two-shot bookbinding adhesive

- Make a Difference 2020

- Problem Solving: Paper Straws in Drinking Beverages

- Stronger straws sustainable future

- Substances of Interest in Disposable Absorbent Hygiene Products

- March (4)

- April (4)

- May (4)

- June (5)

- July (2)

- August (5)

- September (2)

- October (1)

- November (3)

- December (2)

-

2020

- January (4)

- February (2)

- March (3)

- April (4)

- May (3)

-

June (7)

- Community Support in the Era of Coronavirus

- HBFuller Employee Creates Face Shields with 3D Printer

- Improved Packaging Integrity and Greater Customer Satisfaction

- Liquid-Resistant Paper Straws

- What is a Sealant?

- What Is the Future of Commercial Disinfectants?

- Winning over consumers with e-commerce packaging solutions

-

July (6)

- Employees Take Action to be Part of Healing and Growth

- Gain a competitive advantage with packaging adhesive solutions

- HB Fuller Company Foundations Commitment to Communities

- Packaging Solutions for the South African Agriculture Market

- Supporting Organizations That Provide STEM Education for Youth

- Where Does Sustainability Stand Amid COVID-19

- August (3)

- September (2)

- October (4)

- November (2)

- December (4)